Key components and processes of a Water Treatment Plant include:

Coagulation and Flocculation: Chemicals are added to raw water to destabilize suspended particles and create larger aggregates called flocs, making it easier to remove impurities during subsequent treatment steps.

Sedimentation: Floc-laden water is allowed to settle in sedimentation basins, where gravity causes the heavier particles to settle at the bottom. Clarified water is then collected from the top.

Filtration: The clarified water undergoes filtration through layers of sand, gravel, or other media to further remove fine particles, bacteria, and microorganisms.

Disinfection: Disinfectants such as chlorine or chloramines are added to kill harmful pathogens (bacteria, viruses, and protozoa) and prevent the growth of disease-causing microorganisms.

pH Adjustment: The pH of treated water is adjusted to an appropriate level to ensure its stability, taste, and compatibility with distribution systems and consumers.

Chemical Treatment: Additional chemicals may be added to address specific water quality issues, such as pH adjustment, hardness reduction, and removal of iron, manganese, or organic compounds.

Membrane Filtration: Advanced treatment processes, such as membrane filtration (including reverse osmosis and ultrafiltration), are used to remove smaller particles, dissolved salts, and contaminants.

Advanced Oxidation Processes (AOPs): AOPs involve using advanced chemical reactions or processes, such as ozone or UV radiation, to further degrade and remove organic and inorganic pollutants.

Fluoridation: In some cases, fluoride is added to drinking water at controlled levels to prevent dental cavities.

Residuals Management: Residuals generated during the treatment process, such as sludge from sedimentation and filtration, are managed and disposed of properly.

Monitoring and Testing: Water quality is continuously monitored and tested at various stages to ensure compliance with regulatory standards and safe drinking water guidelines.

Distribution: Treated water is pumped into a distribution system of pipes, tanks, and reservoirs that deliver clean water to consumers’ homes, businesses, and other facilities.

Automation and Control Systems: WTPs often use automation and control systems to regulate treatment processes, monitor water quality parameters, and optimize system performance.

Water Treatment Plants are designed based on factors such as raw water quality, treatment goals, capacity requirements, and available technology. They play a critical role in safeguarding public health by providing safe and reliable drinking water while minimizing the impact on the environment. Proper operation, maintenance, and adherence to regulatory standards are essential to ensure the continued effectiveness of Water Treatment Plants.

Key components and processes of a Sewage Treatment Plant include:

Preliminary Treatment: In this stage, large debris, solid materials, and grit are removed from the wastewater using screens, grit chambers, and other mechanical processes to prevent damage to equipment and clogging in subsequent treatment stages.

Primary Treatment: Wastewater flows into sedimentation tanks or clarifiers, where heavier solids settle to the bottom as sludge, while lighter particles and organic matter float to the surface as scum. The clarified wastewater, also known as primary effluent, is then removed from the middle layer.

Secondary Treatment: Biological treatment processes are used to further break down organic matter and remove dissolved and suspended pollutants. Aerobic bacteria, often in activated sludge systems or biological filters, consume organic materials and transform them into sludge. This stage significantly reduces the concentration of pollutants.

Tertiary Treatment: Tertiary treatment involves additional advanced processes to further improve the quality of the treated effluent. These processes may include filtration, chemical treatment (such as disinfection with chlorine or ultraviolet light), and nutrient removal (nitrogen and phosphorus).

Sludge Treatment and Disposal: The sludge generated during the treatment process undergoes further treatment, which may include thickening, dewatering, and stabilization. The treated sludge can be used for beneficial purposes such as land application or converted into biogas for energy generation.

Effluent Discharge or Reuse: The final treated wastewater, known as effluent, is either discharged into receiving bodies of water (rivers, lakes, oceans) in compliance with regulatory standards or may be treated further for non-potable reuse, such as irrigation, industrial processes, or environmental replenishment.

Odor Control: Measures are taken to control odors produced during the treatment process to minimize nuisances for nearby communities.

Monitoring and Testing: Wastewater quality is continuously monitored and tested at various stages to ensure that effluent meets regulatory standards for discharge or reuse.

Automation and Control Systems: Sewage treatment plants often use advanced automation and control systems to optimize treatment processes, monitor key parameters, and ensure efficient operation.

Sewage treatment plants vary in size and complexity, depending on factors such as population served, regulatory requirements, and available technology. Proper operation, maintenance, and compliance with environmental regulations are essential to ensure the effective treatment of sewage and the protection of public health and the environment.

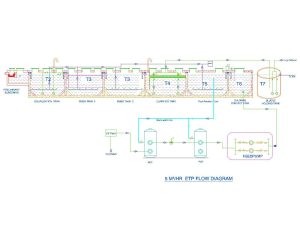

Key components and processes of an Effluent Treatment Plant include:

Preliminary Treatment: Similar to sewage treatment, preliminary treatment involves the removal of large debris, solids, and grit from the effluent using screens, settling tanks, and other mechanisms.

Primary Treatment: Effluent flows into primary sedimentation tanks or clarifiers, where solids settle and are removed as sludge. This primary treatment step reduces the concentration of suspended solids and some organic matter.

Secondary Treatment: Various biological treatment processes are employed to further break down organic pollutants in the effluent. Common secondary treatment methods include activated sludge processes, biological filters, and sequencing batch reactors.

Tertiary Treatment: Tertiary treatment may be required to achieve higher levels of effluent quality. This stage involves additional treatment processes such as advanced filtration, chemical coagulation and flocculation, and disinfection (chlorination, UV treatment) to remove remaining contaminants and pathogens.

Chemical Treatment: In some cases, chemical treatment is used to adjust pH levels, remove specific pollutants, or enhance the performance of biological treatment processes.

Sludge Treatment and Disposal: Similar to sewage treatment, the sludge generated during effluent treatment is further treated, dewatered, and managed. It can be converted into biogas, used for energy generation, or disposed of in an environmentally responsible manner.

Effluent Reuse: Depending on the quality of the treated effluent, some industries may choose to reuse the treated water for non-potable purposes such as irrigation, cooling, or industrial processes.

Monitoring and Compliance: Effluent quality is continuously monitored and tested to ensure compliance with regulatory standards and permit requirements.

Automation and Control Systems: Advanced automation systems are often used to optimize treatment processes, monitor key parameters, and ensure consistent and efficient operation.

Waste Minimization: Industries may implement waste minimization strategies to reduce the volume and toxicity of effluent generated at the source.

Effluent Treatment Plants are tailored to the specific needs and characteristics of different industries, taking into consideration factors such as the type of pollutants generated, production processes, and regulatory requirements. Proper design, operation, and maintenance of ETPs are essential to ensure effective treatment and environmental protection while promoting sustainable industrial practices.

WhatsApp us